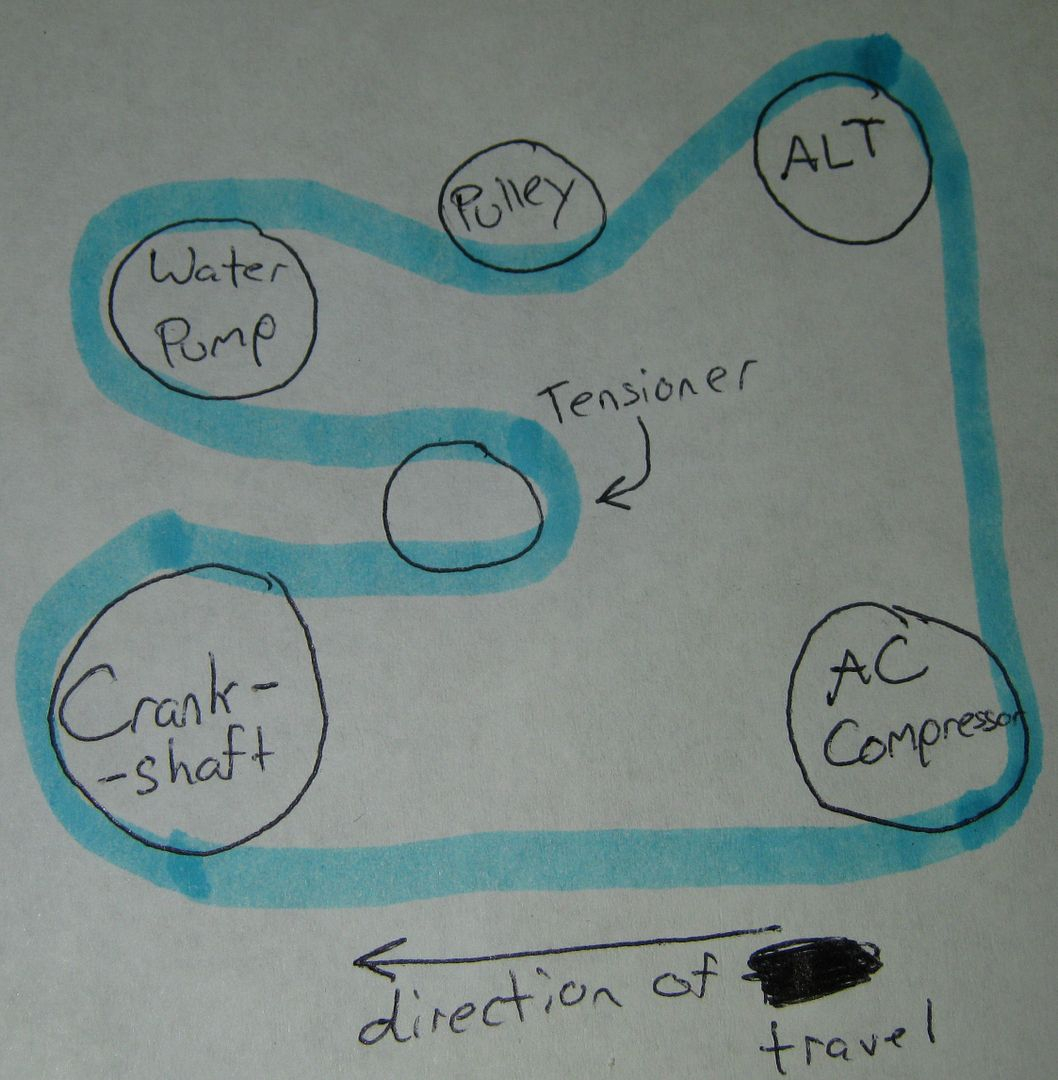

Toyota 3.4 Belt Diagram – Belt diagrams are an essential tool for comprehending the design and routing of belts in various mechanical systems. They offer visual representations of the way belts are connected to different parts. This helps engineers, mechanics and DIY enthusiasts who work on engines, HVAC systems or other equipment driven by belts.

Types of Belt Diagrams

- Serpentine belt diagrams will be utilized when a single, continuous, belt drives several devices.

- Timing belt diagrams show the placement and alignment of a timing belt, which connects the crankshaft to camshaft(s) and ensures proper valve timing in the engine.

- V belt diagrams show the placement of multiple V-shaped conveyor belts in older engines and systems that are specialized.

Key Components of Belt Diagrams

- A pulley is surrounded by a circle and belts that are looped. It is a device that transfers the power from one component to the next.

- Belts are flexible bands that transmit power from pulleys to ground.

- Tensioners ensure a consistent tension on the belt to avoid sliding and ensure that it works effectively.

How to Read a Belt Diagram

- Understanding symbols lets you recognize parts and routing patterns within a schematic.

- The diagram shows the arrangement of important components, like pulleys/belts/tensioners.

- The analysis of routing patterns shows how the belt moves through it and influences various elements.

Here’s a step-by-step guide for creating the belt diagram:

- Gather Important Information Measure precisely and explain the belts, components, and their arrangement

- Sketch the initial plan: Sketch a plan for the system that includes each pulley or tensioner.

- Add Pulleys and Tensioners.

- Draw a Belt Routing Diagram. Sketch the belt’s path around pulleys.

- Make adjustments to your diagram.

Tips and Tricks to Belt Diagram Design

- The use of software tools can make creating professional-looking drawings easier, more precise, and more efficient.

- Achieving accurate and precise information from manufacturer specifications and service manuals, or other reliable online sources is essential to create an accurate and valuable belt diagram.

- Double-checking your diagram for any errors prior to when you submit it to the editor ensures accuracy and reliability. This eliminates any confusion that might be created during repairs or maintenance.

Conclusion

The ability and understanding to construct belt diagrams are vital for anyone working with belt-driven machines. If you have a good understanding of the various components and the correct way to construct them, you’ll be better equipped to tackle any project involving pulleys or belts. Use our tips and tricks to make precise, clear diagrams that make your work easier and more efficient.