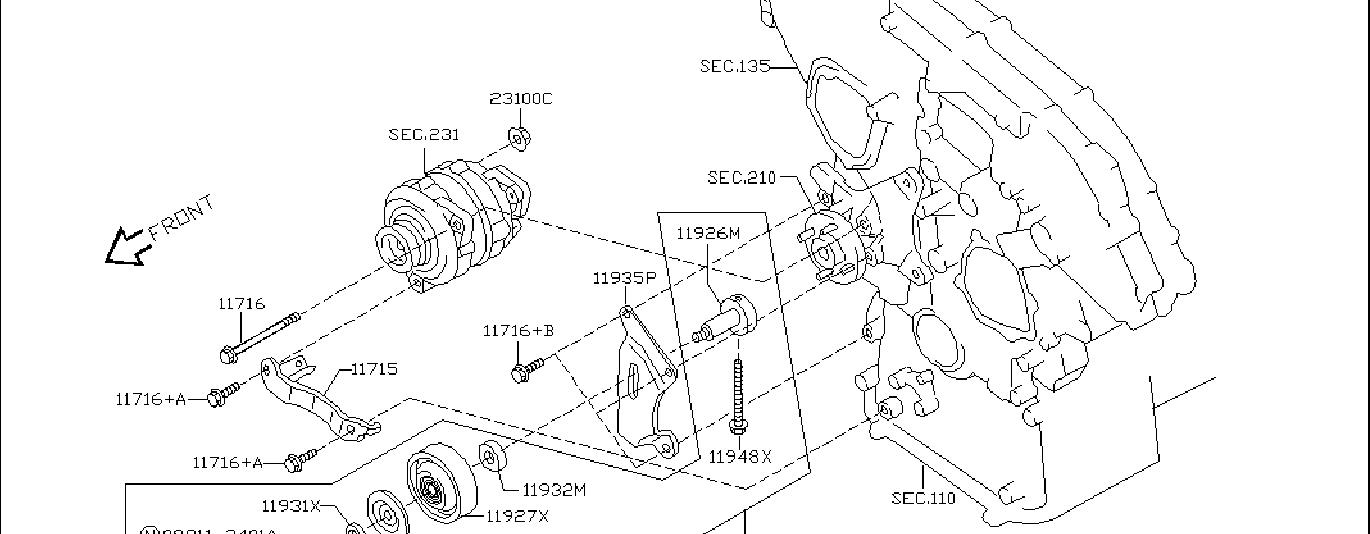

Nissan 350z Belt Diagram – Belt diagrams are a great tool to help understand the layout and routing of belts in various mechanical systems. They show how belts are mounted around various components, aiding mechanics, engineers, and DIY enthusiasts when working on engines, HVAC systems, and other belt-driven equipment.

Types Of Belt Diagrams

- Serpentine belt diagrams can be used in the event of a single, continuous belt driving multiple devices like an alternator, power steering pump, as well as an air conditioning compressor.

- Timing diagrams illustrate how a timing belt is connected to the crankshaft. This helps ensure the proper timing of an engine’s valves.

- V belt diagrams illustrate the location of various V-shaped conveyor belts within older engines and specialized systems.

Belt Diagrams the most important components

- Pulleys are circular machines that loop around belts and transfer power from one part to another.

- Belts transfer energy between pulleys.

- Tensioners maintain correct tension on the belt to prevent slippage and ensure smooth operation.

What do I need to know in order to read a belt diagram

- Understanding symbols helps to discern the components and patterns of routing in diagrams.

- This diagram illustrates the arrangement of important components, such a pulleys/belts/tensioners.

- The ability to interpret patterns of routing will reveal how the belt travels through it and how it affects different elements.

This is a step-by -step guide to create a belt diagram.

- Important Information: Measure and describe the components and belts precisely and arrange them correctly

- Sketch an Initial Layout Sketch an outline of the layout of the system, with each pulley and tensioner.

- Add Pulleys and Tensioners Label each pulley or tensioner with its corresponding component (e.g., power steering pump, alternator).

- Draw the Belt Routing Chart The route is drawn by drawing the belt around the pulleys. Make sure that it follows any manufacturer or industry guidelines.

- Refine your diagram.

Tips and Tricks for Belt Diagram Design

- Utilizing tools in software can make it easier and more accurate more efficient to design professional-looking diagrams

- The secret to creating a detailed and useful belt diagram is obtaining accurate details from specifications of the manufacturer or service manuals.

- Checking the diagram twice for any errors prior to when you submit it to the editor ensures accuracy and security. This eliminates any confusion that might be created during repairs or maintenance.

Conclusion

Anyone who is working in belt-driven systems must be able to comprehend and construct belt diagrams. If you’ve got a solid understanding of the components and the correct way to construct them, you will be more equipped to tackle any task that requires pulleys or belts. These tips and tricks can help you draw clear and precise diagrams that will be more efficient and effective.