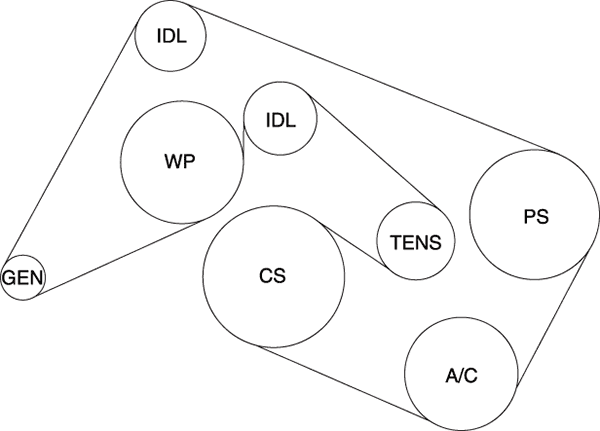

Mercedes E350 Serpentine Belt Diagram – Belt diagrams are a must-have tool to comprehend the layout and routing for belts within various mechanical systems. These diagrams show the way belts are positioned around different parts. This is helpful for mechanics, engineers as well as DIY enthusiasts and anyone who works on engines, HVAC systems and other equipment that is driven by belts.

Types Of Belt Diagrams

- Serpentine belt diagrams can be employed when a single continuous belt is driving multiple devices.

- Timing belt diagrams explain the location and method of aligning the timing belt. It connects the crankshaft with the camshaft(s) that assures the proper timing of valves.

- V -belt diagrams show how V-shaped belts can be placed in older engines, or other specialized systems.

Principal Components of Belt Diagrams

- Pulleys can be an elongated device in the belts that are looped. They transfer power from one component to another.

- Belts can be described as flexible bands that transfer power to pulleys.

- Tensioners ensure the correct tension on the belt, to avoid slippage and guarantee the smooth operation.

How to read a Belt Diagram

- The understanding of symbols and notations can help identify components and routing pattern on a diagram.

- The recognition of crucial components like pulleys and belts allows you to see the structure of the system.

- Understanding the pattern of routing reveals how the belt travels across it, and how it impacts different elements.

A step-by-step procedure for making a belt chart

- Gather Important Information: Measure accurately and describe components, belts, and their arrangement

- Sketch the initial plan: Sketch a system plan that includes each pulley or tensioner.

- Add Pulleys and Tensioners.

- Create the Belt Routing Schema: Sketch out the route of your belt(s) around pulleys. Make sure you follow any manufacturer or industry standards.

- Make any adjustments to your diagram.

Tips to Belt Diagram Design

- Software tools can help simplify the creation of professional-looking diagrams.

- For creating a precise and functional belt diagrams, it’s essential to obtain accurate information from the manufacturer’s specifications, service manuals, and other trustworthy online sources.

- Double-checking any errors before completing your diagram ensures the accuracy.

Conclusion

Anyone working with belt-driven systems needs to be able to understand and construct belt diagrams. By becoming familiar with the different kinds of diagrams, their components and the best way to build them properly will make you more ready to tackle any job involving belts or pulleys. These tips and tricks will assist you in creating detailed and clear diagrams that will be more efficient and effective.