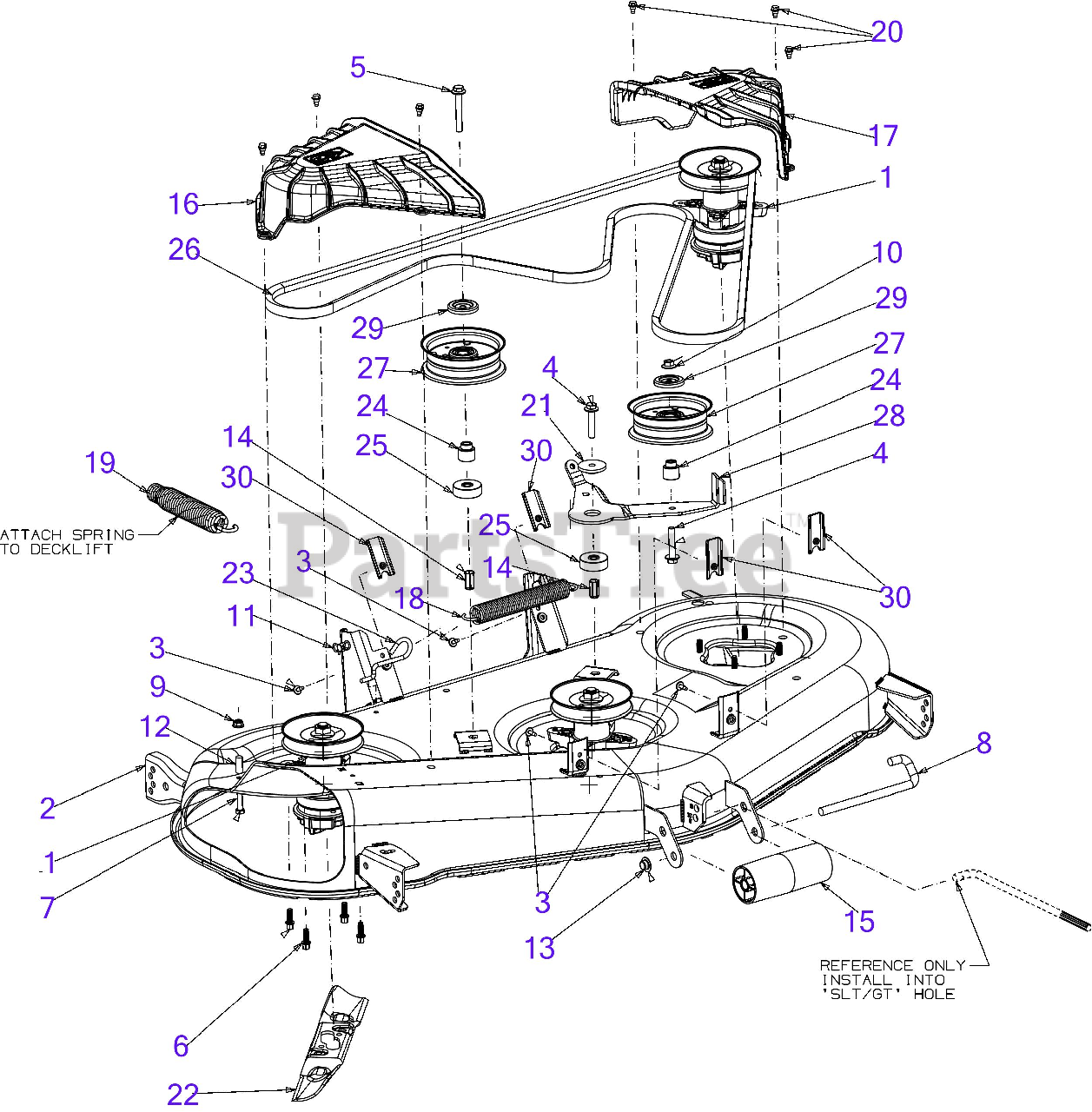

Cub Cadet Xt2 Belt Diagram – Belt diagrams offer an image of the layout and routings of belts in different mechanical systems. They show the way belts are connected to different components. This helps mechanics, engineers and DIY enthusiasts who work on HVAC systems, engines or other equipment driven by belts.

Types Belt Diagrams

- Serpentine belt diagrams will be employed when a single continuous, belt drives several devices.

- Timing belt diagrams depict the alignment and placement of a timing belt, that connects the crankshaft with camshaft(s), ensuring proper valve timing in the engine.

- V Belt Diagrams illustrate the function and location of various V-shaped belts inside older engines, or other special systems.

Key Components in Belt Diagrams

- A pulley is a device that has a circle around it and belts that loop. It transmits energy from one part to the next.

- Belts, which are elastic bands that transmit power between pulleys, are referred to as

- Tensioners maintain proper tension on the belt to prevent slippage and ensure a smooth operation.

How to Read a Belt Diagram

- Understanding symbols and notations aids in identifying the components and patterns of routing in the diagram.

- You can see the design of the system by drawing out key componentslike belts, pulleys, or tensioners.

- The way to interpret the routing pattern shows how the belt travels across it, and how it impacts different elements.

The following is a step by process guide for making a Belt Diagram

- Gathering important information Measure, describe and organize components, belts and their arrangements accurately.

- Sketch The First Layout.

- Add Pulleys and Tensioners.

- Create the Belt Routing Schema Draw the route of your belt(s) around pulleys. Make sure to adhere to any standards set by the manufacturer or industry.

- Improve your diagram.

Tips and tips for making Belt Diagrams

- Utilizing software tools can make creating professional-looking diagrams easier, more precise, and more efficient.

- The secret to creating a detailed and useful belt diagram is obtaining accurate details from specifications of the manufacturer or service manuals.

- Double-checking for errors before making your diagram final ensures accuracy and dependability, eliminating potential issues or confusion when performing repairs or maintenance.

Conclusion

Anybody who works with belt-driven machines needs to be able to draw belt diagrams. You’ll be more prepared tackle any project that involves pulleys or belts if you are familiar with the various types of diagrams and their parts. These tips and tricks will aid you in creating clear and precise diagrams that will make your work more efficient.