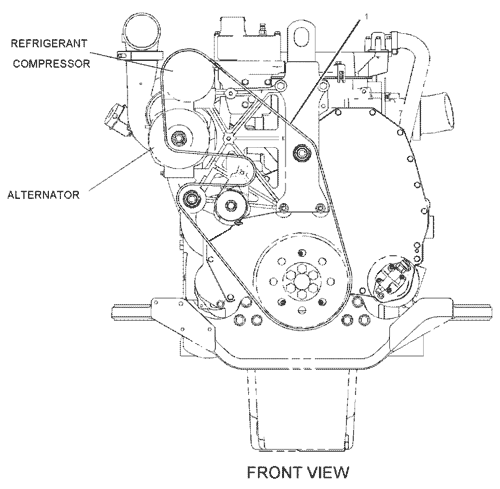

Caterpillar C13 Belt Routing Diagram – Belt diagrams are vital tools to understand the arrangement and routing of belts in different mechanical systems. They are visual representations that show how belts are mounted around parts. This can be useful for engineers, mechanics, and DIY enthusiasts working on HVAC systems, engines, or other belt-driven machinery.

Types of Belt Diagrams

- Serpentine belt diagrams can be utilized in the event of a single, continuous belt driving multiple devices like an alternator or power steering pump as well as an air conditioning compressor.

- Timing belt diagrams depict the position and alignment of a timing belt which connects the crankshaft to camshaft(s) and ensures that the valves are properly synchronized in the engine.

- V belt diagrams demonstrate the placement of multiple V-shaped conveyor belts in older engines as well as specialized systems.

Principal Components of Belt Diagrams

- A pulley is a device that is surrounded by a circle and belts that loop. It is a device that transfers energy from one part to another.

- Belts transfer power between pulleys.

- Tensioners keep the right tension of your belt, preventing slippage.

How to Read the Belt Diagram

- Understanding symbols notations, symbols and how they work can help you understand the various components and routing patterns that are part of the diagram.

- You can see the design of the system by drawing out key components, such as belts, pulleys, or tensioners.

- Understanding the pattern of routing reveals how the belt moves through it and interacts with various components.

This is a step-by- procedure for creating a Belt Diagram:

- Gathering important information: Measure, specify and organize components, belts and their arrangement accurately.

- Sketch the Layout Initial: Sketch out a basic plan of the system including every pulley and tensioner’s location.

- Add Pulleys and Tensioners.

- Design the Belt Routing Schema Sketch out the path of your belt(s) around pulleys. Make sure to adhere to any manufacturer or industry standards.

- Review and refine your diagram: Double-check each of your work for accuracybefore making any necessary adjustments to make a clear and straightforward diagram.

Tips and Tricks to Belt Diagram Creation

- Software tools can simplify the process of creating professional-looking diagrams.

- The secret to creating a precise and useful belt diagram is accurately gathering information from manufacturer specifications or service manuals.

- Double-checking your diagram’s accuracy before you send the finalized version guarantees security and helps avoid issues when you make repairs.

Conclusion

An understanding and ability to construct belt diagrams are essential skills for anyone working with belt-driven machines. By becoming familiar with the different types of diagrams, their elements and methods of constructing them correctly will make you more ready to tackle any job involving belts or pulleys. Utilize our suggestions and tricks to make precise, clear diagrams that will help you work more efficiently and more effective.