2023 Jeep Grand Cherokee 5.7 Serpentine Belt Diagram – Belt diagrams are essential tools to comprehend the routing and layout of belts within various mechanical systems. These diagrams illustrate how belts are connected to different components. This is beneficial for engineers, mechanics, DIY enthusiasts, and all those working on HVAC systems, engines and other equipment that is driven by belts.

Types and applications of Belt Diagrams

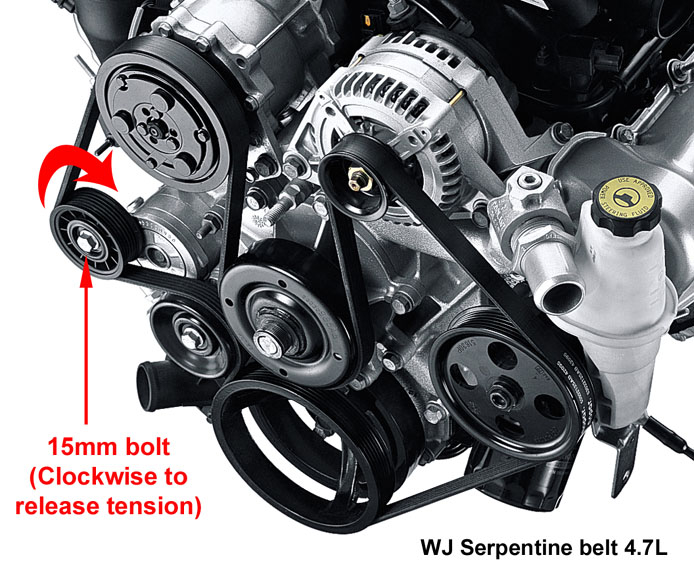

- Serpentine belt diagrams will be used when a single, continuous, belt drives multiple devices.

- Timing belt diagrams show the location and the alignment of a timing chain, which connects the crankshaft with camshaft(s), in order to ensure proper valve timing.

- V-belt diagrams illustrate the way that V-shaped belts are placed in older engines, or other systems with specialized features.

The key components of Belt Diagrams

- Pulleys, also known as circular devices with belts looped around them, transmit power from one area to the next.

- Belts are elastic bands that transmit power from pulleys to ground.

- Tensioners maintain proper tension on the belt to prevent slippage and ensure efficient operation.

How to read a Belt Diagram

- Understanding the meaning of symbols notations, symbols and the way they are used can help you understand the various components and routing patterns within the diagram.

- The recognition of important components such as belts and pulleys allows you to see the system’s layout.

- Understanding patterns of routing helps to understand how the belt moves around it and affects other components.

This is a step-by step guide on creating an outline of a belt:

- Gather Important Information: Accurately measure and specify the components, belt(s), and their placement.

- Sketch an Initial Layout Create a sketch of the system’s layout, with every pulley and tensioner.

- Add tensioners and pulleys Label each pulley or tensioner with the appropriate component (e.g., power steering pump, alternator).

- The Belt Routing Diagram. Draw the belt route around pulleys.

- Review and refine your diagram: Double-check all of your work to ensure accuracy. making any changes necessary to make a clear and straightforward diagram.

Tips, Tricks and Methods to Build a Belt Diagram

- The use of software tools can make designing professional-looking diagrams easier more precise and efficient.

- It is vital to collect accurate data from specifications of the manufacturer and service manuals in order to create a useful belt diagram.

- Double verifying the accuracy of your diagram prior to when you submit the finalized version guarantees security and helps avoid issues that may arise during repairs.

Conclusion

Anyone who is working with machines that are driven by belts must learn how to draw diagrams of belts. This will make you better prepared to tackle any task involving belts or pulleys by being familiar with the different types of belts, their components, and how to construct them properly. Utilize our suggestions and tricks to make clear, precise diagrams that will help you work more efficiently and more efficient.