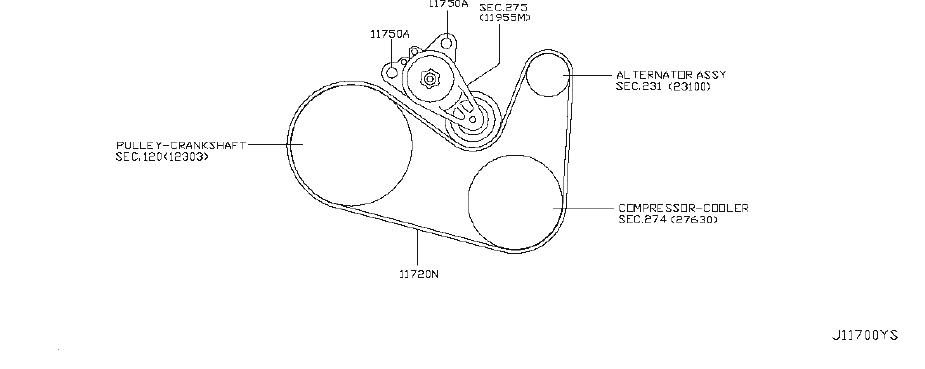

2023 Nissan Quest Belt Diagram – Belt diagrams are vital tools to understand the design and routing of belts within different mechanical systems. They show the way belts are connected to various components. This helps mechanics, engineers and DIY enthusiasts working on engines, HVAC systems and other equipment that is driven by belts.

Types of Belt Diagrams

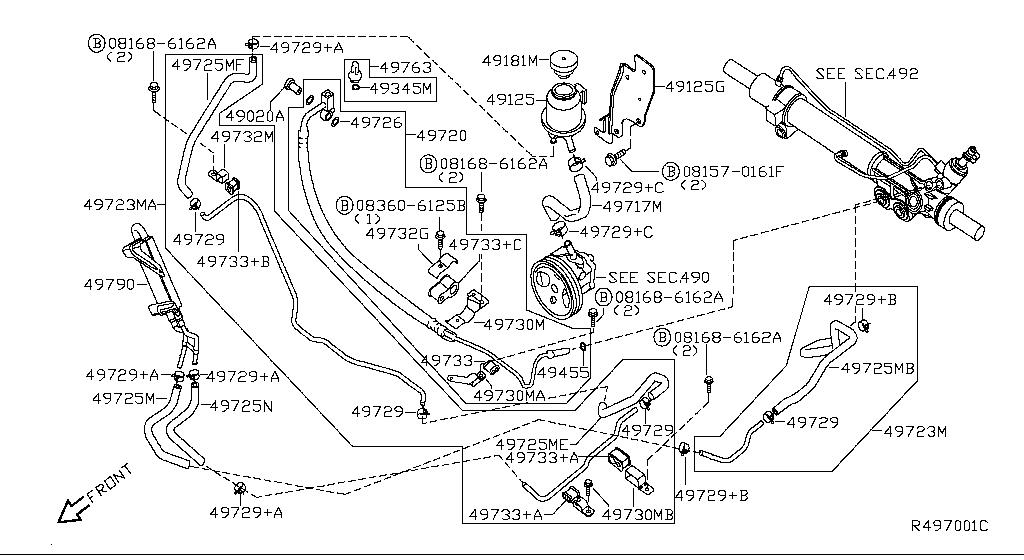

- Serpentine Belt Diagrams are utilized when a single continuous belt is operating multiple components like an alternator, power steering pump compressor for air conditioners power steering pump, and others.

- Timing diagrams illustrate how a timing belt is connected to the crankshaft. This ensures proper timing of an engine’s valves.

- V-belt diagrams illustrate the location of several V-shaped belts in older engines or specialized systems, each of which drives an individual component.

Belt Diagrams The Key Components

- Pulleys are an object that is circular around the belts that are looped. They transfer power from one part to another.

- Belts can be described as flexible bands that transmit power to pulleys.

- Tensioners ensure the correct tension on your belt to prevent slippage.

What can I do to read a Belt Diagram

- Understanding symbols or notations can assist you to discern the parts and routing patterns in a diagram.

- This diagram shows the arrangement of key components, such a pulleys/belts/tensioners.

- Interpreting routing pattern reveals how the belt moves across it, and how it impacts different elements.

This is a step-by-step tutorial on creating an outline of a belt:

- Gather Important Information Take precise measurements and write down components, belts, and their placement

- Sketch The First Layout.

- Add Pulleys and Tensioners.

- Draw the Belt Routing Diagram Draw the course of the belt(s) around pulleys, being sure to follow the specifications of the manufacturer or industry standards for the proper routing.

- Refine your diagram.

Tips and Tricks to Belt Diagram Creation

- Software tools can simplify the process of creating professional-looking diagrams.

- It is vital to collect accurate data from specifications of the manufacturer and service manuals in order to create a useful diagram of the belt.

- Double-checking errors before finalizing your diagram will ensure accuracy.

Conclusion

For those who use belt-driven machines, it’s essential to have a good understanding of how to create belt diagrams. This will allow you to be better prepared to tackle any task that involves belts and pulleys by becoming familiar with the different types of belts, their components, as well as how to construct them properly. Utilize our tips and tricks for producing clear, precise diagrams that will make your work easier and more effective.