2023 Grand Prix Gtp Belt Diagram – Belt diagrams are a must-have tool to understand the layout and routing for belts in different mechanical systems. These diagrams illustrate how belts are placed around different components. This is beneficial for mechanics, engineers as well as DIY enthusiasts and anyone who works on HVAC systems, engines and other equipment that is driven by belts.

Types Of Belt Diagrams

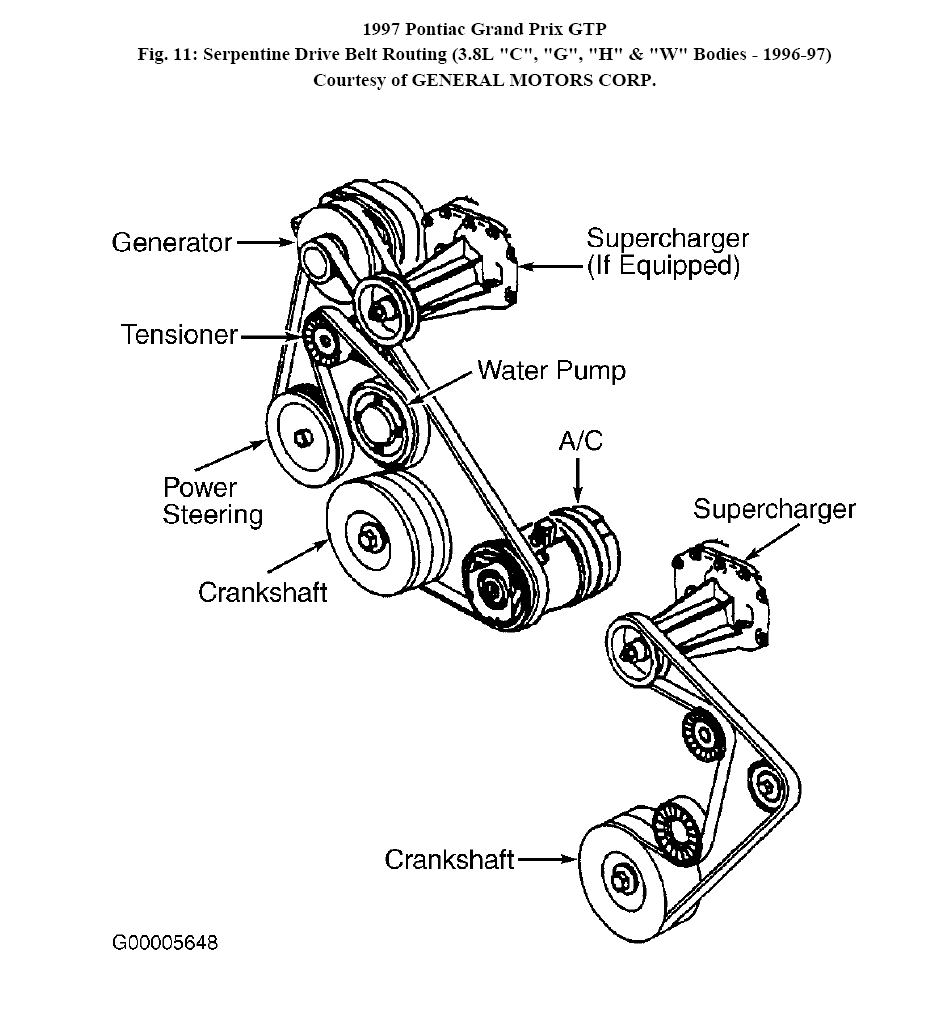

- Serpentine belt diagrams will be used when a single, continuous belt is used to drive multiple devices.

- Timing-belt diagrams show where and how to align the timing belt. It connects the crankshaft to the camshaft(s) and ensures that the valve is properly timed.

- Vbelt diagrams depict multiple Vshaped belts being installed in older engines.

The most important components for Belt Diagrams

- Pulleys can be a circular device around the belts that are looped. They transfer power from one component to another.

- Belts, the elastic bands that transfer power between pulleys, are called

- Tensioners keep the belt in a tight place to avoid slippage.

How to read the Belt Diagram

- Understanding symbols aids in discern the components and patterns of routing in the diagram.

- You can visualize the layout of the system through drawing out key components, such as belts, pulleys and tensioners.

- The ability to understand patterns of routing will reveal the way that the belt moves through it and how it affects different elements.

This is a step-by-step instruction to create the belt diagram.

- Gather Important Information Measure and describe accurately the components, belt(s), and their location.

- Sketch the Initial Plan: Sketch a system plan that includes every pulley and tensioner.

- Add Tensioners and Pulleys.

- Draw the Belt Routing Chart The route is drawn by drawing the belt in the direction of the pulleys. Be sure it follows any guidelines from the manufacturer or industry.

- Reveal and improve your diagram.

Tips and Tricks for Belt Diagrams

- Utilizing tools in software can make it easier and more accurate more efficient to produce professional-looking diagrams

- It is essential to gather details from manuals for service, manufacturer specifications, and other reliable online sources in order create an efficient and accurate belt diagram.

- Double-checking your diagram for errors prior to finalizing your diagram guarantees reliability and accuracy, avoiding any potential problems or confusion that might arise during repairs or maintenance tasks.

Conclusion

If you’re a user of belt-driven systems, it is vital to have an understanding of how to design belt diagrams. If you have a thorough understanding of the components and how to correctly construct them, you’ll be better equipped to tackle any task that requires belts or pulleys. Use our suggestions to create precise and clear diagrams that boost efficiency and efficiency.