2023 G6 Serpentine Belt Diagram – Belt diagrams are an image of the layout and routing of belts in various mechanical systems. They offer visual representations of the way belts are positioned on various parts, helping mechanics, engineers, and DIY enthusiasts in working on engines, HVAC systems, or any other belt-driven machines.

Types of Belt Diagrams

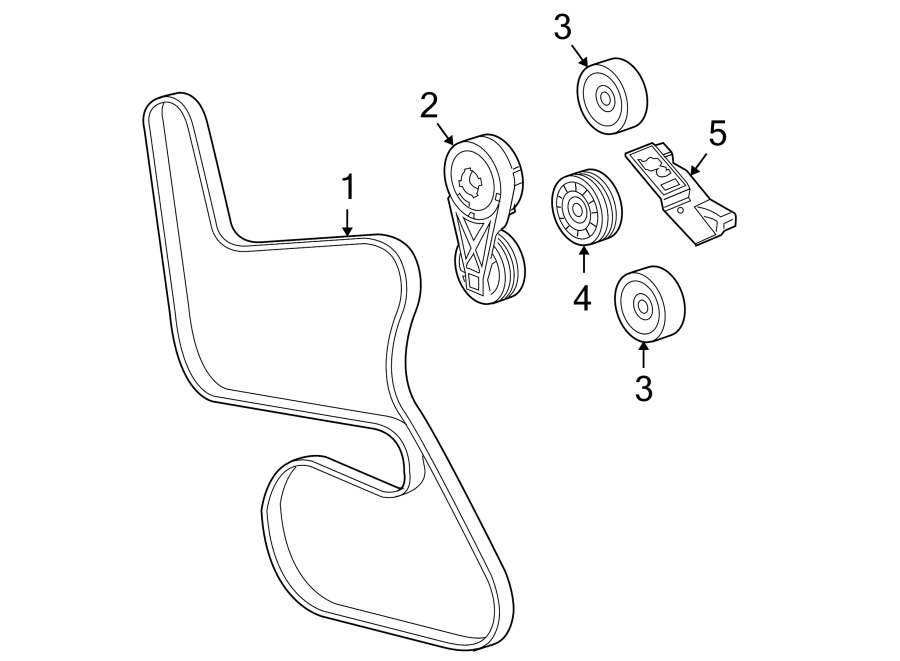

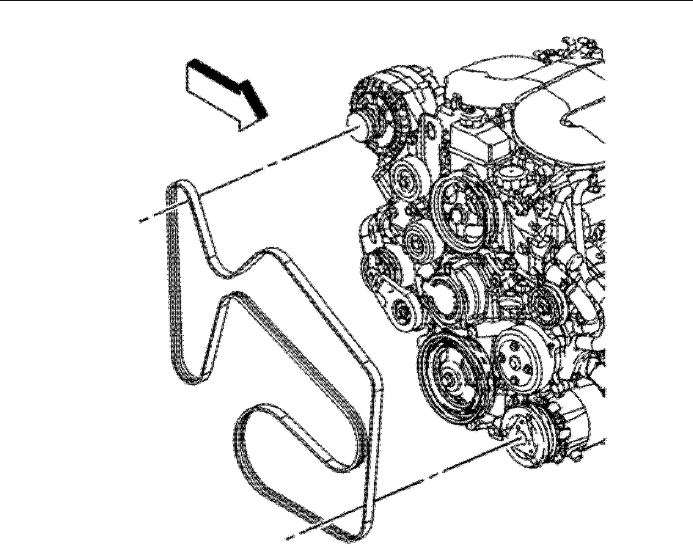

- Serpentine diagrams are used for a single belt that is used to drive multiple devices such as an alternator or power steering pumps or an air conditioning compressor.

- Timing belt diagrams show the placement and alignment of a timing belt, which connects the crankshaft to camshaft(s) to ensure the proper timing of valves in the engine.

- Vbelt diagrams depict numerous V-shaped belts that are fitted in older engines.

Belt Diagrams: Key Components Diagrams

- Pulleys are a circular device around which belts are looped. They transfer power from one element to the next.

- Belts, which are the elastic bands that transmit power between pulleys, are referred to as

- Tensioners hold the belt in a tight place to avoid slippage.

How to read a Belt Diagram

- Understanding symbols or notations can help discern the parts and routing patterns in the diagram.

- Identification of crucial components like pulleys belts, and tensioners allows you to visualize the structure of the system.

- Interpreting routing patterns reveals how the belt moves through it and affects various elements.

We’ve prepared a step by-step guide for making belt diagrams:

- Gather Important Information Be precise in measuring and describing components, belt(s), and their placement.

- Sketch The Initial Layout.

- Add Tensioners and Pulleys.

- Draw the Belt Routing Chart Draw the path of the belt in the direction of the pulleys. Be sure it follows any manufacturer or industry guidelines.

- Review and improve your diagram.

Tips and Tricks for Belt Diagrams

- With the appropriate software tools, designing professional-looking diagrams can be made simpler, faster and cost-effective.

- To create a precise and functional belt diagram, it is crucial to gather accurate data from the manufacturer’s specifications, service manuals, or other trustworthy online sources.

- Double-checking errors before finalizing your diagram ensures accuracy.

Conclusion

Anyone working using belt-driven machines must be able to draw belt diagrams. Knowing the difference between diagrams, how they’re constructed, and how you can properly build them will help you be more equipped to tackle any task that requires pulleys or belts. These tips and tricks will assist you in creating clear, precise diagrams to improve your efficiency.