2023 Ford F150 5.4 Serpentine Belt Diagram Without Ac – Belt diagrams are essential to understand the layout and routing for belts within various mechanical systems. They illustrate the arrangement of belts around various parts. This helps engineers, mechanics as well as DIY-lovers who work on engines, HVAC, or any other equipment driven by belts.

Types of Belt Diagrams

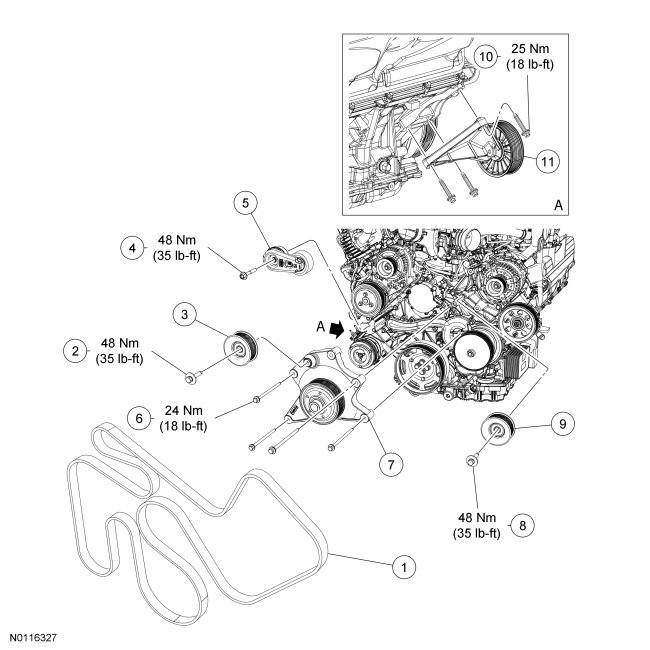

- Serpentine belt diagrams are employed when there is a single continuous belt that is driving several devices such as an alternator, power steering pump and air conditioning compressor.

- Timing belt diagrams demonstrate the location and alignment of a timing chain that connects the crankshaft to camshaft(s) in order to ensure the proper timing of valves.

- V -belt diagrams show how multiple V-shaped belts are placed in older engines, or other systems with specialized features.

Belt Diagrams: Key Components Diagrams

- The Pulleys are circular devices that wrap belts around, transferring power to a single component.

- Belts transfer energy between pulleys.

- Tensioners maintain correct tension on the belt, to avoid slippage and ensure smooth operation.

How to read a Belt Diagram

- Understanding symbols or notations can assist you to discern the parts and routing patterns in the diagram.

- Identification of crucial components like pulleys, belts and tensioners lets users to visualize the system’s layout.

- The analysis of routing patterns shows how the belt moves across it and affects various components.

This is a step-by-step instruction to creating a belt diagram.

- Important Information: Measure and specify the components and belts precisely and arrange them properly

- Sketch The Initial Layout.

- Add tensioners and pulleys Label each pulley and tensioner with its corresponding component (e.g. an power steering pump, alternator).

- Draw an a Belt Routing Diagram. Sketch the belt’s path around pulleys.

- Revise and enhance your diagram.

Tips and Tricks to Belt Diagram Design

- With the right software tools, creating professional-looking diagrams can be made more efficient, quicker, and more cost effective.

- It is essential to get data from manuals for service as well as manufacturer specifications and other trustworthy internet sources in order to produce an accurate and useful belt diagram.

- Double-checking the accuracy of your diagram before you send the finalized version guarantees reliability and prevents any potential issues that may arise in the course of repairs.

Conclusion

A solid understanding of and the ability to draw belt diagrams is crucial for anyone who works with belt-driven systems. Knowing the differences between diagrams, how they’re constructed, and how you can correctly build them will help you be more equipped to tackle any job that requires pulleys or belts. Use our tips and tricks to design detailed, clear diagrams that will help you work more efficiently and more efficient.