2023 Ford F150 5.4 Serpentine Belt Diagram With Ac – Belt diagrams assist you in understanding how belts are arranged in various mechanical systems. They show the way belts are positioned around different parts. This is useful for mechanics, engineers or DIY enthusiasts, as well as anyone who works on engines, HVAC systems and other equipment that is driven by belts.

Belt Types Diagrams

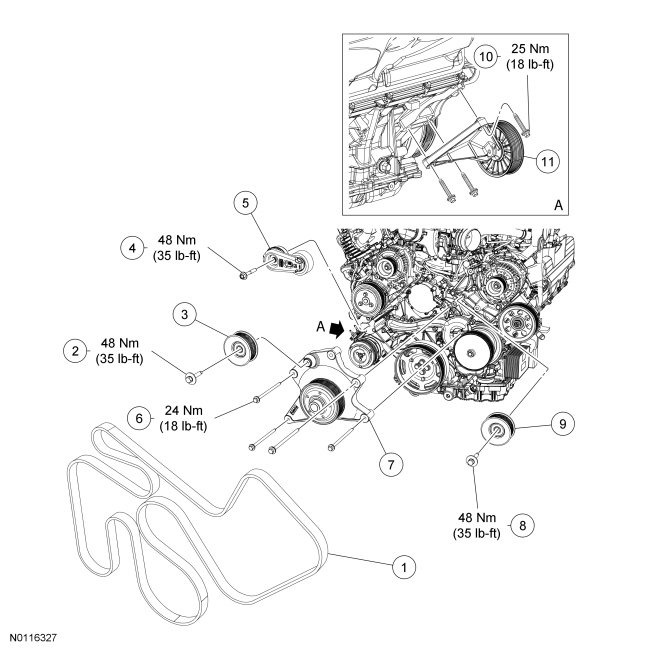

- Serpentine belt diagrams could be utilized for when a single continuous belt powers multiple devices for example, an alternator or power steering pump.

- Timing belt diagrams explain where and how to align a timing belt. It connects the crankshaft to the camshaft(s) that assures the proper timing of valves.

- V -belt diagrams show the way that V-shaped belts are placed in older engines, or in other systems that are specialized.

Principal Components of Belt Diagrams

- A pulley has a circle around it and belts which are looped. It transmits the power from one component to another.

- Belts transfer power between pulleys.

- Tensioners keep the proper tension on the belt to avoid slippage and ensure the smooth operation.

What can I do to read a Belt Diagram

- Understanding symbols can help you recognize the various components and patterns in the diagram.

- You can visualize the design of the system by drawing out key componentslike belts, pulleys or tensioners.

- Understanding routing patterns allows you to see how the belt moves, and how it affects different elements.

We’ve prepared an step-by-step procedure for creating belt diagrams:

- Collect important data Measure, describe and arrange the components, belt(s) and their arrangement

- Sketch the Initial Layout: Sketch out a basic blueprint of the system, including every pulley and the position of the tensioner.

- Add Pulleys and Tensioners.

- Draw the Belt Routing Chart: Draw the route of the belt in the direction of the pulleys. Be sure it is in line with any industry or manufacturer guidelines.

- Refine your diagram.

Tips and Tricks to Belt Diagram Design

- Utilizing software tools could make creating professional-looking diagrams much more simple, precise, and efficient.

- It is crucial to get accurate information from specifications of the manufacturer and service manuals in order to draw a helpful belt diagram.

- Double-checking your diagram’s accuracy before you send the final version ensures reliability and prevents any potential problems when you make repairs.

Conclusion

It is important to be prepared and confident in the ability to build belt diagrams for people who work with belt-driven system. This will allow you to be more prepared for any project involving belts and pulleys by becoming familiar with the various types, their components, and how to construct them properly. You can use our tips to make accurate and clear diagrams that boost efficiency and effectiveness.