2023 E320 Belt Diagram – Belt diagrams help you understand the way belts are placed in various mechanical systems. These diagrams show the way belts are positioned around various components. This is useful for engineers, mechanics or DIY enthusiasts, as well as those who work on HVAC systems, engines and other equipment that is driven by belts.

Belt Types Diagrams

- Serpentine belt diagrams may be utilized in situations where a single belt drives multiple devices, for example, an alternator or power steering pump.

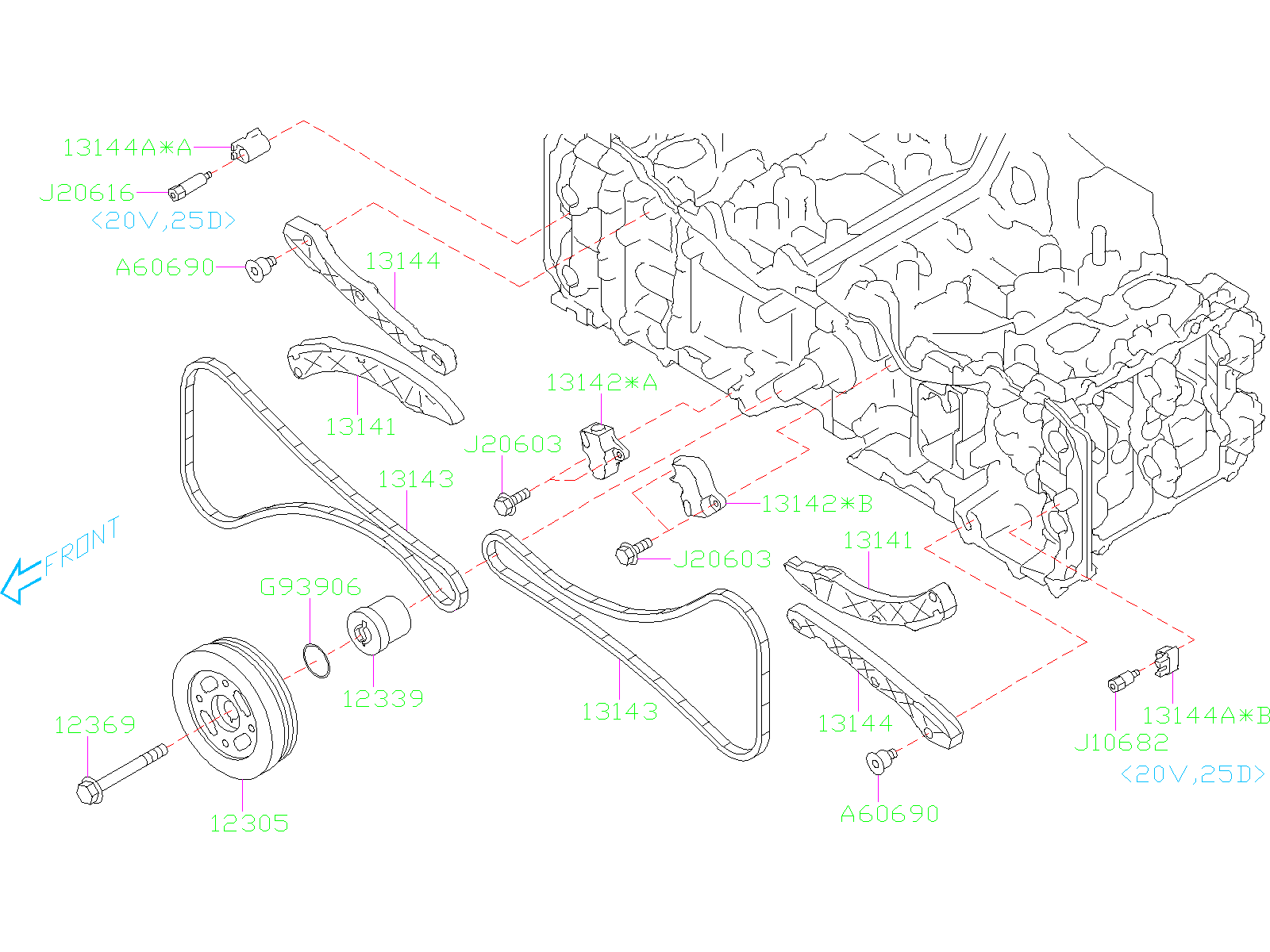

- Timing Belt Diagrams illustrate the positioning and alignment of the timing belt which connects the crankshaft and camshaft(s) to ensure the correct timing for valves.

- V -belt diagrams show how V-shaped belts can be installed in older engines or other specialized systems.

Belt Diagrams The Key Components

- Pulleys, which are circular devices that have belts looped around them, transfer power from one area to another.

- Belts are elastic bands that transmit power from pulleys to the ground.

- Tensioners ensure an appropriate tension on the belt to prevent slippage and ensure a smooth operation.

What can I do to read the Belt Diagram

- Understanding symbols and notations helps identify components and routing patterns in a diagram.

- The identification of crucial components such as belts and pulleys allow you to view the layout of the system.

- Understanding routing patterns allows you to observe how the belt moves, and how it affects different elements.

A step-by-step procedure for making a belt chart

- Gathering of Important Information Measure, describe and organize components, belts and their arrangements precisely.

- Sketch the initial plan: Sketch a system plan that includes each pulley or tensioner.

- Add Tensioners and Pulleys: Label every pulley or tensioner with the component that it is associated with (e.g. alternator or power steering pumps).

- The Belt Routing Diagram. Draw the belt routing around pulleys.

- Review and improve your diagram.

Tips, Tricks and Strategies for Belt Diagram Construction

- Software tools can help simplify the process of creating professional-looking diagrams.

- Accurately gathering accurate information from the specifications of manufacturers, service manuals or trustworthy online sources is crucial to produce an accurate and efficient belt diagram.

- Double-checking for errors before finalizing your diagram guarantees precision and reliability, eliminating potential issues or confusion in maintenance or repairs.

Conclusion

Anyone working with belt-driven machines needs to be able to draw diagrams of belts. When you’re familiar with the different types of diagrams, their components and the best way to build them properly, you’ll be better prepared to tackle any project that involves pulleys or belts. These suggestions and tricks will help you create clear and precise diagrams that can be more effective and efficient.