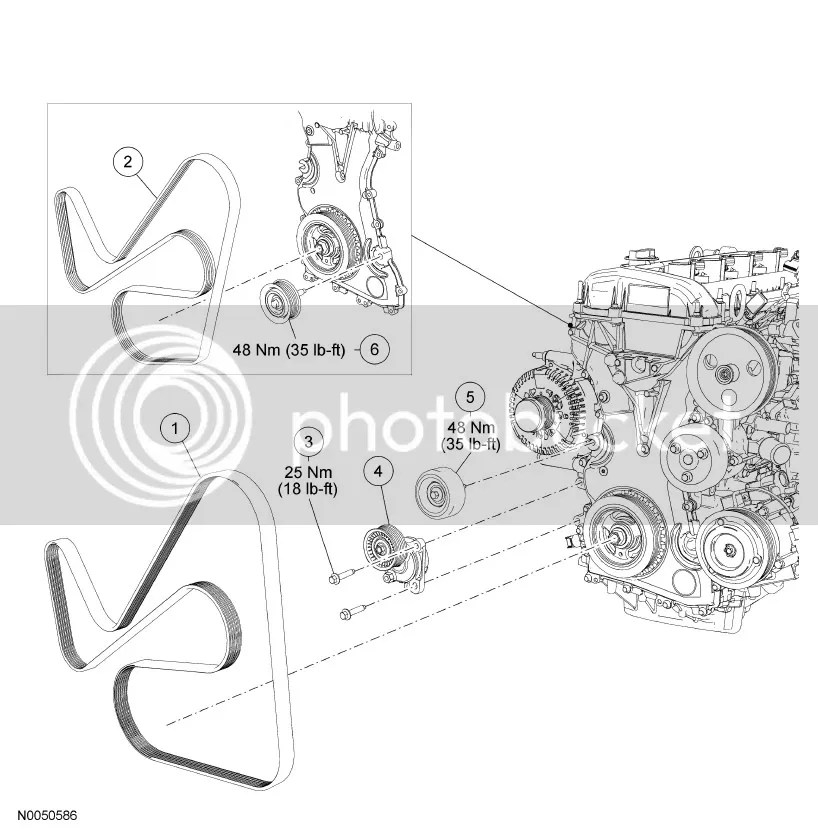

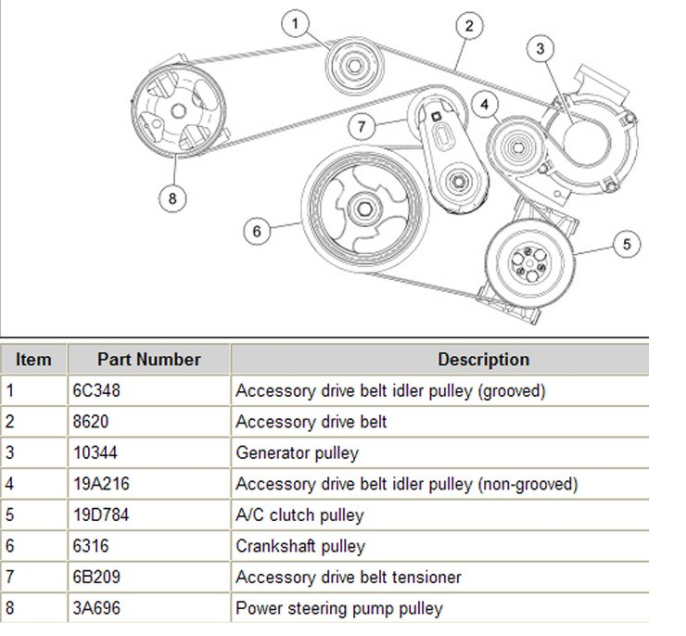

2.5 Ford Fusion Belt Diagram – Belt diagrams assist you in understanding the way belts are placed within various mechanical systems. They offer visual representations of the way belts are positioned around various components, aiding mechanics, engineers, as well as DIY enthusiasts when working on HVAC systems, and other equipment driven by belts.

Types and applications of Belt Diagrams

- Serpentine diagrams are used for a single belt which can drive multiple devices, such as an alternator, power steering pumps, or an air cooling compressor.

- Timing belt diagrams explain the location and method of aligning a timing belt. It connects the crankshaft to the camshaft(s), which ensures that the valve is properly timed.

- Vbelt diagrams show numerous V-shaped belts that are placed in older engines.

The most important components of Belt Diagrams

- Pulleys, also known as circular devices with belts that loop around them, transfer power from one area to another.

- Belts can be described as elastic bands that transfer power to pulleys.

- Tensioners ensure the correct tension on your belt, preventing slippage.

How to Read a Belt Diagram

- The understanding of symbols and notations can assist you to identify components and routing pattern in the diagram.

- Identification of the most important components like pulleys, belts, and tensioners allow you to see the layout of the system.

- The capability to analyze routing patterns can reveal the way that the belt moves through it and how it affects different components.

This is a step-by- step guide to creating a Belt Diagram:

- Gather Important Info: Measure accurately and describe components, belts, and their placement

- Sketch the initial plan: Sketch an outline of the system that includes each pulley or tensioner.

- Add Tensioners and Pulleys. Label each pulley with its component (e.g. power steering pump or alternator).

- The Belt Routing Diagram. Draw the belt routing around pulleys.

- Review and refine your diagram: Double-check every aspect of your work for accuracy, making any necessary modifications to make a clear and simple diagram.

Tips and techniques for making a Belt Diagram

- With the right software tools, designing attractive and professional-looking diagrams is simpler, faster and cost-effective.

- The most important thing to create an accurate and valuable belt diagram is accurately gathering information from manufacturer specifications or service manuals.

- Double-checking your diagram for any errors prior to when you submit it to the editor ensures accuracy and security. This eliminates any confusion that may occur during maintenance or repairs.

Conclusion

A solid understanding of and the ability to draw belt diagrams is essential skills for anyone working using belt-driven systems. If you’ve got a solid understanding of the various components and how to correctly construct them, you’ll be better equipped to tackle any task that requires belts or pulleys. Utilize our tips and tricks for creating clear, precise diagrams that help you work easier and more effective.