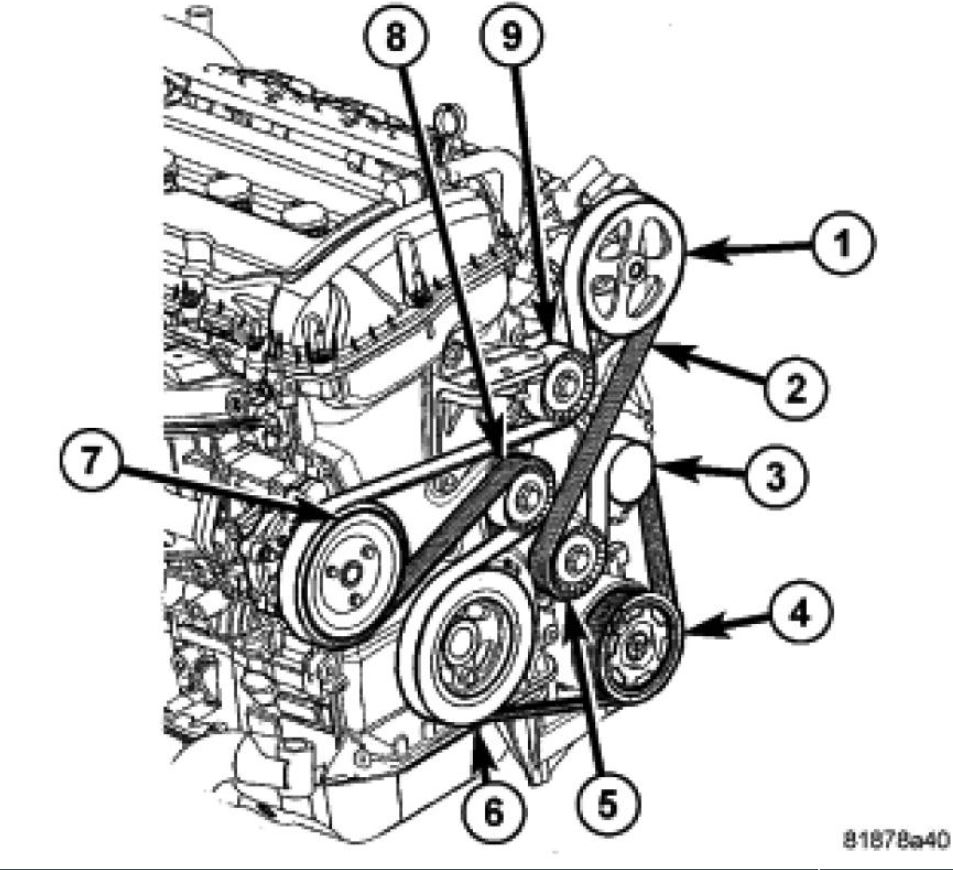

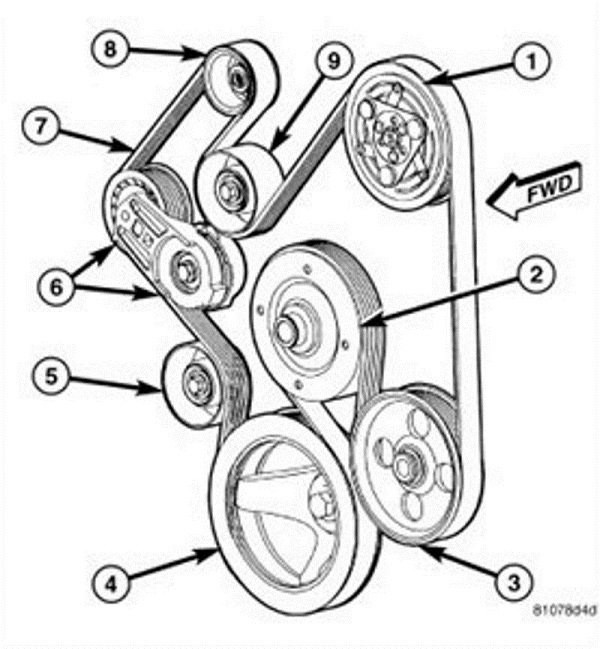

08 Dodge Caliber Serpentine Belt Diagram – Belt diagrams are a great tool to aid in understanding the routing and layout of belts in different mechanical systems. They illustrate the arrangement of belts around various parts. This is helpful to engineers, mechanics and DIY-lovers when they are working on HVAC systems, engines or other belt-driven equipment.

Types and Applications of Belt Diagrams

- Serpentine diagrams are used for a single belt which is used to drive multiple devices such as an alternator, power steering pumps, or an air conditioning compressor.

- Timing diagrams illustrate the way a timing belt is connected to the crankshaft. This ensures proper timing of the engine’s valves.

- V belt diagrams illustrate the placement of multiple V-shaped conveyor belts in older engines and specialized systems.

Belt Diagrams The Key Components

- Pulleys are an elongated device in the belts that are looped. They transfer power from one part to another.

- Belts, which are the elastic bands that transmit power between pulleys, are referred to as

- Tensioners hold the belt in a straight position to prevent slippage.

How do I read a Belt Diagram

- Understanding symbols can help you discern the components and patterns of routing in diagrams.

- Identifying key components such belts, pulleys, tensioners and belts lets you visualize the system’s layout.

- The ability to understand patterns of routing can show how the belt moves through it and how it affects different elements.

This is a step-by-step tutorial to create an outline of a belt:

- Gather Important Information Measure precisely and explain the belts, components, as well as their placement

- Sketch the initial plan: Sketch an outline of the system which includes each pulley or tensioner.

- Add pulleys and tensioners: Label every pulley or tensioner with the corresponding component (e.g. alternator or power steering pumps).

- Draw the Belt Routing Diagram. Sketch the belt’s course around pulleys.

- Make adjustments to the diagram.

Tips and Tricks for Belt Diagram Creation

- Using software tools will make it easier, more accurate, and more efficient to create high-quality diagrams

- Accurately gathering accurate information from specifications of the manufacturer, service manuals or trustworthy online sources is crucial for creating an accurate and efficient diagram of the belt.

- Checking the diagram twice for errors before you finish it will ensure accuracy and the reliability. This will eliminate any confusion that could arise during repairs or maintenance.

Conclusion

It is important to be confident and competent in your ability to construct belt diagrams for people who work with belt-driven system. Knowing the differences between diagrams, the way they are constructed, and how you can effectively create them will make you better equipped to tackle any project with belts or pulleys. Utilize our advice to make precise and clear diagrams that improve efficiency and effectiveness.